.png)

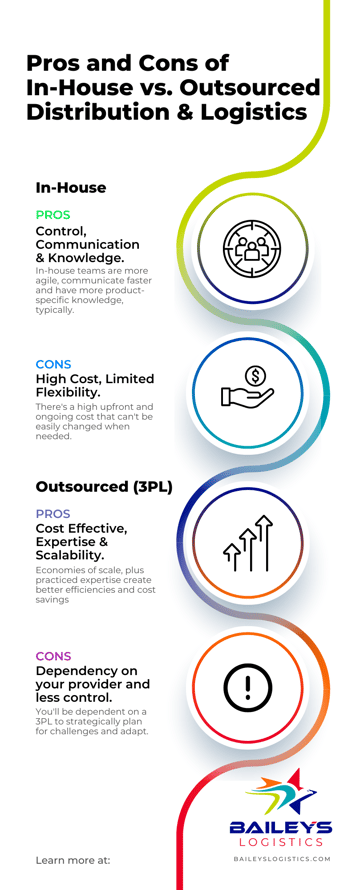

Comparing Pros / Cons of In-House vs. 3PL Distribution Solutions

If you're a small or medium business, and you sell products to consumers, you've undoubtedly spent some time considering your distribution process. And there's an age-old debate: Do it in-house, or outsource it, but how do you decide? You'll have to weigh the pros and cons of an in-house or outsourced (third-party logistics) approach.

Bottom line: In-house solutions offer control and visibility into operations, but can be costly to maintain. Outsourced solutions often provide cost savings, but they can also come with their tradeoffs especially if you don't select the right 3PL.

In-House Distribution Team

In-House Distribution Team

Let's start with In-House Distribution. This means your warehouse, forklifts, racking, labor, and more.

Pros:

Full Control:

When you, as a business manage your own distribution, you retain full control over every aspect of the process, from the initial stages of storage and inventory management to the final stages of delivery. This control allows the company to customize its distribution operations to precisely fit its needs, with the ability to make quick adjustments as necessary.

Additionally, maintaining full control enables the company to align its distribution process more closely with its overall business strategy, objectives, and culture. That may or may not be important to you, but the control can be a real pro. Need new reporting? Just do it. Do you think a new warehouse in Topeka is warranted? Buy it. No need to go through a third party, you just do it.

Direct Communication:

In-house distribution also facilitates more immediate and effective communication. Because all members of the distribution team are part of the same organization, they can work together more cohesively and resolve issues more quickly. If you're having a problem, it's usually as easy as walking out into the warehouse and having a conversation, or maybe a meeting with shift leaders. Information can flow seamlessly between departments, and decisions can be made quickly, reducing the risk of miscommunication or delays.

This level of direct communication can result in more efficient operations and better overall performance of the distribution process. In logistics, communication is everything. The faster the communication, the more efficient the process (usually) so getting more direct communication might just help you build greater efficiency.

In-depth Knowledge:

An in-house distribution team can develop a deep understanding of the company's products, clientele, and business model. The team can become experts in handling specific types of goods, understanding their unique requirements, and addressing any potential challenges associated with their storage or transport. This intimate knowledge can translate into superior customer service, as the team is well-equipped to answer customer queries and resolve issues effectively and promptly.

This becomes more important the more unique your products are. It's not to say that a 3PL can't be knowledgeable, but when your team spends 100% of their time only on your products, they'll get to know them well. They'll help avoid problems that cause damage, and help get priority customers (or problematic ones) resolved quickly before they devolve into madness because they know and are aware of the impacts they have on service. And that is the real benefit.

Cons:

High Initial and Ongoing Investment:

One of the primary drawbacks of in-house distribution is the significant initial investment required. Companies need to invest in infrastructure, such as warehouses and vehicles, and may also need to invest in technology systems for inventory management, order processing, and route planning. There's no telling how much this would cost you because it depends. But even the smallest companies can find themselves spending hundreds of thousands per year. The big ones, tens of millions.

And the initial investment isn't the only problem: the ongoing costs associated with maintaining and upgrading this infrastructure can be substantial. Truck repairs, racking maintenance, software administrators, and what can seem like at least 1000 handheld scanners or all kinds that break down entirely too often. On top of that, companies also need to recruit, hire, and train employees to manage and operate their distribution network. There's a cost to that, and an HR administrative cost to maintain it.

The biggest con here is that you can't easily change that investment if your distribution needs suddenly change, up or down. What if you no longer need that warehouse in Topeka? It'll be months or years before you could sell it. Suddenly need 50 new trucks for a new client? It'll take a while to acquire those, and do you know the best channels to go to get them?

Staffing Challenges:

Managing an in-house distribution team requires dealing with various staffing challenges, such as recruiting, training, and retaining skilled logistics professionals. Companies need to ensure they have the right personnel to efficiently manage the distribution process, which can involve a significant investment of time and resources. Logistics isn't a simple thing, although observing it, it can seem fairly straightforward.

Getting people who know how to optimize a warehouse, or run them in the most efficient way can save you millions, but also cost you time and effort to find. Good schedulers are key people too, to keep your warehouse organized on when things come in and go out. And, it goes on. Finding and keeping the right skills in your warehouse can be hard when it's more alluring for those people to work for companies like FedEx, Amazon, DHL, or other logistics companies that have more upward mobility and opportunity for them.

In addition, companies must deal with issues such as staff turnover, managing peak demand periods, and ensuring employee safety and satisfaction. All of these are challenges that likely have a different set of requirements than the rest of your employee base because in short, you're running two companies: your main company, and a mini logistics company.

Limited Flexibility:

In-house distribution will limit your company's flexibility. Scaling up operations to handle increased demand can be a slow and expensive process, as it may involve acquiring more space, purchasing additional vehicles, or hiring more staff. Similarly, if demand drops, the company may find itself with excess capacity, leading to inefficiency and wasted resources. In-house teams may also find it challenging to adapt to changes in business operations or to incorporate new technologies or practices into their distribution process.

This is because in the end flexibility is about percent change. If you have to make a change that represents shifting 50% of your team or space or technology to something new, it can feel like your whole world gets shifted upside down. Whereas, if you're a logistics company, that same request might only change 5% of their capacity because they handle you, and 20 other clients. The same change might feel like only a minor shift, but to an in-house team, it can feel cataclysmic. It's easy to make a 5% change, but much harder to make a big shift. That flexibility, or lack thereof, is one of the key hindrances of companies that run their distribution efforts.

Outsourcing to a 3PL

So what's the alternative? Outsourced Distribution using a 3PL, or third-party logistics provider. What you'll see, is that in most cases, it's the flip side of the in-house coin. But let's review some key points to consider.

Pros:

Cost-Effective:

Outsourcing distribution to a third-party logistics (3PL) provider can be a cost-effective choice for many businesses. With a 3PL, companies can avoid the significant capital expenditures associated with establishing and maintaining their own warehouses, vehicles, and distribution personnel. Additionally, because 3PLs serve multiple clients, they can achieve economies of scale that individual businesses might not be able to realize on their own.

These cost savings can then be passed on to their clients, making outsourced distribution a financially attractive option. In logistics, two things matter: time and efficiency. With a 3PL, they have more time working logistics, and more efficient processes that have developed over that time (hopefully). They have larger facilities, more resources, and more skill, generally. All of this, adds up to savings over what it costs you to do the same effort. Granted, there will be an administrative overhead fee because the 3PLs have to make a profit, but you can still often save a good amount of money, especially on capital expenditure.

Lastly, one of the costs that isn't discussed enough: the cost of mistakes. When you organize your own warehouse incorrectly, it can cost you millions over time. But, it's often a hidden cost. Did you structure your deliveries and inbound shipments efficiently to avoid moving items too many times? That can cost you too. These are mistakes that many in-house teams make because they're still learning. But 3PLs have already gone through that, and that knowledge, saves you the cost of those mistakes.

Scalability:

Another significant advantage of outsourcing is the scalability it offers. 3PL providers can swiftly adjust to changes in a company's size or distribution needs. Whether it's dealing with seasonal fluctuations, sudden spikes in demand, or long-term growth, a capable 3PL can adapt to changes more quickly and with less disruption than an in-house team. This flexibility can be especially beneficial for businesses in fast-paced industries or those experiencing rapid growth, or in businesses that are prone to recession drop-offs.

Think about these common scenarios: customer orders have dropped off due to economic conditions, and aren't due to return for 24-48 months. You suddenly have hundreds of thousands of empty positions in your warehouse, a warehouse you are paying for monthly. You'll take a hit unless you can release warehousing costs.

Or what about a manufacturer who, due to a seasonal opportunity, can produce your product at a much lower rate temporarily, provided you can take a large amount of the product immediately? Where would you put it? It's only temporary, so you don't want to buy another warehouse.

None of these would be concerns with a 3PL because they can help you quickly scale up and down depending on your needs, so your costs are aligned with your current revenue projections.

Expertise:

3PL providers are experts in logistics and distribution. They have the knowledge, experience, and technologies necessary to optimize the distribution process. Whether it's implementing advanced inventory management systems, planning efficient delivery routes, or handling customs paperwork for international shipping, a 3PL's expertise can add significant value. Moreover, 3PLs stay updated on the latest industry trends and regulations, ensuring that your distribution operations remain compliant and competitive.

We discussed this above when we said: "finding and keeping the right skills in your warehouse can be hard when it's more alluring for those people to work for companies like FedEx, Amazon, DHL, or other logistics companies that have more upward mobility and opportunity for them." And this is true because, with larger economies of scale, or specialized logistics businesses, they're set up to attract the best talent. That talent, combined with the expertise can save you potentially millions of dollars over time.

And even if that's not enough, consider that a 3PL has likely years and years more experience than your in-house team would in dealing with a variety of challenging scenarios. There's a common phrase in logistics that says: "80% of what you'll experience in logistics, can happen to you in your first year. But the other 20%, takes a lifetime to experience". A 3PL brings that other 20% to bear for you, to save you money, save you headaches, and help you run better. All the while, giving you the best shot at performing at the highest level for your customers.

Cons:

Less Control:

When outsourcing distribution, businesses relinquish some control over their logistics operations. While a good 3PL provider will maintain close communication and align their services with the client's objectives, it's not the same as having direct control over every aspect of the distribution process. Companies may have less flexibility to make on-the-fly adjustments or to tailor the distribution process to their specific needs. A good 3PL can minimize that gap, but no matter how good they are, it isn't quite the same as being able to "run down to the warehouse". That control, that flexibility, and that agility is something that just has to be given up when you go to a 3PL.

Dependence on Provider:

Outsourcing distribution also means depending on the 3PL provider's reliability and efficiency. If the provider experiences problems - such as technical issues, labor disputes, or financial instability - these can disrupt the client's distribution operations and potentially harm their reputation with customers. Therefore, it's critical to choose a reliable and reputable 3PL provider. In this article, we've discussed some real pros to using a 3PL, but these all assume that the 3PL you choose is A-tier. If you choose a 3PL that doesn't have the experience or won't listen to you and your needs, you will become dependent, and in worst-case, held hostage by a 3PL.

So we reiterate: Choose Wisely. A 3PL that works for you, hears your needs, and adapts to you, will give you great benefits. So maybe, being dependent on a provider like that isn't a con. But if your 3PL isn't adaptable, or doesn't have enough experience to weather the challenges that come, or isn't able to strategically plan ahead as they should, your dependence on them can become a real negative for your business.

Potential Communication Gaps:

While a competent 3PL provider will strive to maintain clear and open communication, outsourcing can sometimes lead to communication gaps. Information might flow less immediately than with an in-house team, and misunderstandings can occur, particularly if different languages or time zones are involved. Businesses must put in place effective communication strategies to mitigate these potential challenges when working with a 3PL provider.

One incredibly common problem is that 3PLs might believe that their "portal" is their communication. Talking to them, it might seem as if logging in to their portal might hold every answer you'll ever need - but there are a lot of times when a phone call, or maybe even an in-person visit might be necessary. When those needs arise, the good 3PLs separate from the bad ones. Good 3PLs fight with you, in the trenches, to make sure you have every communication necessary. Email, Phone, Text, Portal, Meeting, etc. Bad ones, will give up on communicating or maybe even avoid your communications entirely.

This can be a challenging thing to see when looking at buying from a 3PL. Everyone will say they have great communication, so it's worth doing some research. See if they'll let you talk to current customers, or if they'll work with you regularly to address and improve any challenges that may come up regarding communication.

Conclusion

Ultimately, there is no right answer for everyone. Every business needs to weigh the pros and cons of both options when it comes to in-house vs. outsourced distribution solutions, ensuring they have the best solution for their company’s specific needs. With the right partner or team in place, businesses can achieve successful results no matter what option they choose.